You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need Improvement Idea For Stove Rigidity

- Thread starter CiK01

- Start date

LongWayAround

WKR

- Joined

- Aug 10, 2015

- Messages

- 2,297

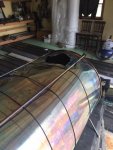

I have the same problem with my home made stove. I copied another member's tutorial for a keg stove to make it.

I have a rifle hunt coming up in a few days and thought I would try putting the pipe in with the end ring inside the stove body. I'm not sure what the consensus is on that but my issue has been feeling like I didn't have enough pipe depth into the stove.

I have a rifle hunt coming up in a few days and thought I would try putting the pipe in with the end ring inside the stove body. I'm not sure what the consensus is on that but my issue has been feeling like I didn't have enough pipe depth into the stove.

Is that from inserting it (if so slow down and take time, FYI the ring does go on the bottom of the pipe on the inside to make the pipe round) or the damper resting on it? If the damper I put the rods right up against the stove pipe, I have a bit of dimple on each side from it but nothing like that.

- Thread Starter

- #4

Is that from inserting it (if so slow down and take time, FYI the ring does go on the bottom of the pipe on the inside to make the pipe round) or the damper resting on it? If the damper I put the rods right up against the stove pipe, I have a bit of dimple on each side from it but nothing like that.

It is definitely from inserting the pipe, and it is definitely from me going to fast. The damage is done already, that is why I am looking for ideas on how to make it stronger.

Beendare

WKR

You could cut a little piece of shim stock to overlay that spot. Say a 6" x 6" piece with a hole cut to match your stovepipe.

I'm assuming you have the damper. If you keep your bars close to the opening the weight of the pipe is transferred to the damper and then to the bars putting almost no weight on the opening in the shim.

I'm assuming you have the damper. If you keep your bars close to the opening the weight of the pipe is transferred to the damper and then to the bars putting almost no weight on the opening in the shim.

- Thread Starter

- #7

Thanks guys.

Dotman, I don't have anything to compare it to, but if it seems right to you...I feel better.

Beendare, I thought about the same fix. Not sure if it could be welded to it. I will definitely keep those bars closer to the pipe and the damper riding on the bars.

Dotman, I don't have anything to compare it to, but if it seems right to you...I feel better.

Beendare, I thought about the same fix. Not sure if it could be welded to it. I will definitely keep those bars closer to the pipe and the damper riding on the bars.

Mine has done the same. I e-mailed Brennan to see if he had any suggestions for taking any of the dings and dents out of a stove body. His suggestion was to get the stove burning hot and then use a long stick of some sort to apply pressure on the dents from inside for a short period of time. He seems to have good luck doing this with most dents but I have not had a chance to try it yet.

bbrown

WKR

I think a lot of the warping or dents are caused by over-tightening the body supports and only get worse once the stove gets hot. At least that has been my experience so I have gotten in the habit of just getting the body supports snug enough to hold everything together. Once those dents are heat set the only way I have made any progress to reform the metal is while it is hot like described by 530Chukar.

mfllood3800

WKR

I have taken a propane hand held torch, and got the metal red and was able to get 50% of the warping out of mine. It will never be as new, but you can easily get the majority of the ugly out. Just don't get over hot.

Place foil body damaged area on a plate of steel. Heat until red, Pound bad areas with a hammer- worked for me.

Again it doesn't get them all out, but probably close to 1/2 the bad, or really bad areas will come out.

Place foil body damaged area on a plate of steel. Heat until red, Pound bad areas with a hammer- worked for me.

Again it doesn't get them all out, but probably close to 1/2 the bad, or really bad areas will come out.

- Thread Starter

- #13

I have taken a propane hand held torch, and got the metal red and was able to get 50% of the warping out of mine. It will never be as new, but you can easily get the majority of the ugly out. Just don't get over hot.

Place foil body damaged area on a plate of steel. Heat until red, Pound bad areas with a hammer- worked for me.

Again it doesn't get them all out, but probably close to 1/2 the bad, or really bad areas will come out.

I just got around to addressing mine. I took a torch and rubber mallet.......straightened it right out. Good as new if you ask me.

Thanks for the tip on the torch.

Tony

Sent from my iPhone using Tapatalk

JigStick

WKR

Thats impressive damage. How did you manage to do that lol. My SO XL Titanium stove has been abused and the stove jack hole is still round. You could try buying a SO damper assembly. Its flared on the bottom where it goes into the stove. It may fill some of that void in the damage hole. Then put your chimney into the damper assembly.

You could also buy a "wood stove fiberglass gasket" kit from tractor supply. It comes with high temp chimney cement. Glue on the gasket around the base of your stove pipe, and let the gasket fill the void.

Amazon.com: Rutland 96N-6 Grapho-Glas Rope Gasket Replacement Kit, 1/2-Inch by 7-Feet: Home & Kitchen

Hell...you may able to just insert your stove pipe the way it is....and just stuff the gasket around the base. No glue necessary. I bet you that works, and won't weigh much at all. And not affect your ability to roll up the chimney

You could also buy a "wood stove fiberglass gasket" kit from tractor supply. It comes with high temp chimney cement. Glue on the gasket around the base of your stove pipe, and let the gasket fill the void.

Amazon.com: Rutland 96N-6 Grapho-Glas Rope Gasket Replacement Kit, 1/2-Inch by 7-Feet: Home & Kitchen

Hell...you may able to just insert your stove pipe the way it is....and just stuff the gasket around the base. No glue necessary. I bet you that works, and won't weigh much at all. And not affect your ability to roll up the chimney

Similar threads

- Replies

- 7

- Views

- 497

- Replies

- 22

- Views

- 2K

Featured Video

Stats

Latest Articles

-

TT#28 Idaho Bear Hunting with Roger Holscher and Chris Young

-

Rockstar Research with Kevin Monteith

-

Hunting Big Mule Deer: Obey the Wind & Still-Hunting

-

TT#27 DIY New Zealand Hunting with Australian Duo Miller and Pitts

-

Fewer Bucks, More Fawns?

-

Mathews Lift Review

-

Wyoming Range Winter Wrap-Up with Jeff Short

-

The Pursuit with Cliff Gray

-

Mile High Mule Deer Seminar

-

TT#26 Kyle Virgin and the infamous Hobbit Rifle