Cameron C

FNG

- Joined

- Aug 30, 2012

- Messages

- 76

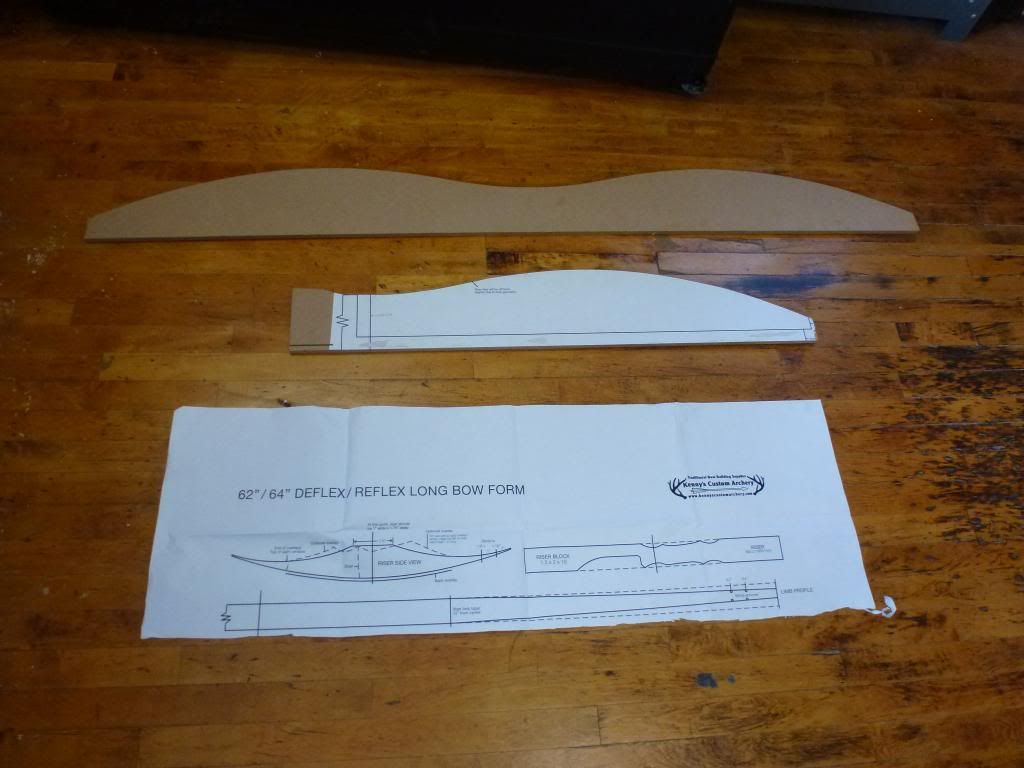

I got a job at a piano company this summer doing some engineering/quality control type stuff. I met this guy upstairs who builds guitars during his lunchbreak, he is an incredible cabinet maker/ woodworker. I mentioned that one day I'd like to build a bow, and without hesitation he says "let's start next week." So I order the fiberglass, Smooth-on glue, and a set of plans from Kenny M, he's a guy on TradGang. Kenny is very knowledgable, and very generous with his information, he took the time to explain the building process to me. I highly recommend doing business with him if you're thinking about ordering lams/glass/glue/whatever build-related.

I won't pretend to know what I'm doing, I'm just going to post photos of the building process. I will be building this bow only on my lunchbreaks at work, so it will take a while. I plan on being done late August. Enjoy!

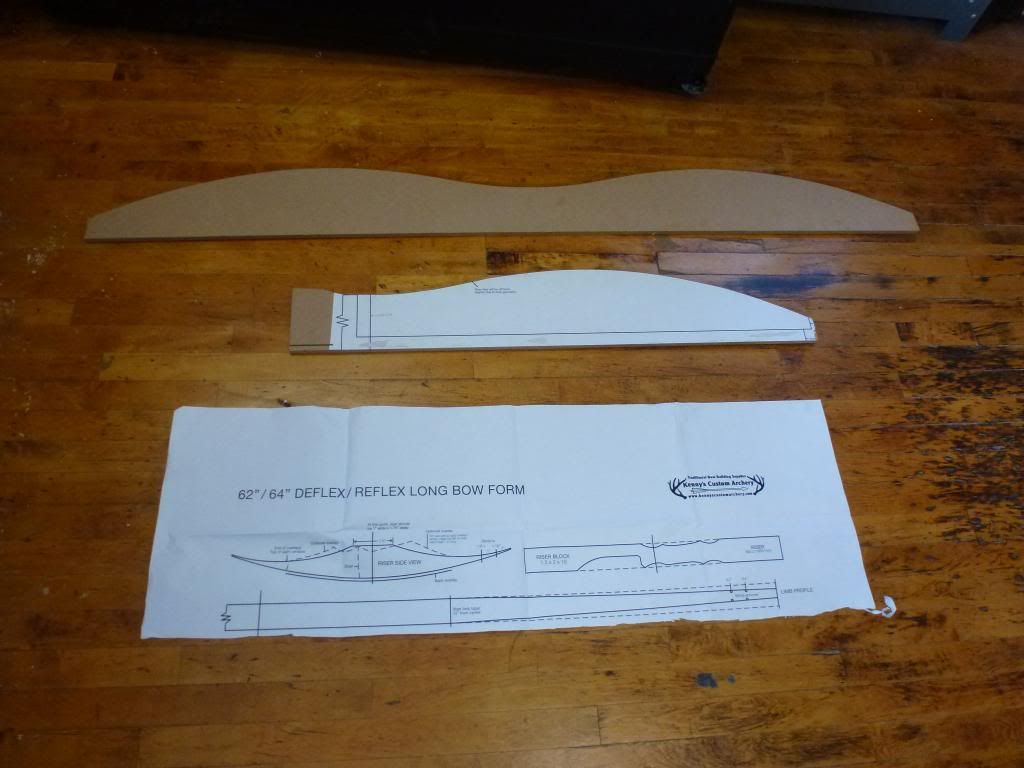

Today I finished up the router template for the bottom part of my caul.

I won't pretend to know what I'm doing, I'm just going to post photos of the building process. I will be building this bow only on my lunchbreaks at work, so it will take a while. I plan on being done late August. Enjoy!

Today I finished up the router template for the bottom part of my caul.