Pgohil

WKR

- Joined

- Feb 16, 2018

- Messages

- 500

7mm rem mag rem 700. 24" barrel.

Unknown Round count.

First load development for this rifle

New Norma brass

Fed 215M PRIMER

Nosler accubond 160

RL 22 powder

Book max is 65

.020 off the lands.

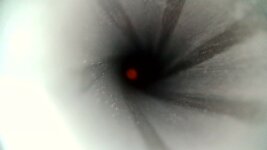

I loaded up rounds from 62.5 to 65 in half grain incriments to see what this rifle liked. The first couple shots the bolt felt a touch sticky, after that it became very stuck. I did not shoot it past 63.5 grains. No bolt swipe, no flatten primers, no cratered primers. Backed all the way down to 62 grains, I'm getting right at 2900 FPS, and just a bit of bolt stick. I can't understand what's causing this.

Today was hot, upper 80s and I was in the full sun reloading at the range for this development. I'm wondering how much the sun was causing an issue. But still I don't think it should cause extraction problems.

The 62 and 1/2 grain load shot incredibly well sub moa 2936 fps and SD 5 , But it does no good if you can't work the bolt!

I'd appreciate any help thanks.

Another thing I noticed when firing a string of three, the last shot was always the hardest to lift and extract That's one reason why I'm thinking heat is an issue.

Unknown Round count.

First load development for this rifle

New Norma brass

Fed 215M PRIMER

Nosler accubond 160

RL 22 powder

Book max is 65

.020 off the lands.

I loaded up rounds from 62.5 to 65 in half grain incriments to see what this rifle liked. The first couple shots the bolt felt a touch sticky, after that it became very stuck. I did not shoot it past 63.5 grains. No bolt swipe, no flatten primers, no cratered primers. Backed all the way down to 62 grains, I'm getting right at 2900 FPS, and just a bit of bolt stick. I can't understand what's causing this.

Today was hot, upper 80s and I was in the full sun reloading at the range for this development. I'm wondering how much the sun was causing an issue. But still I don't think it should cause extraction problems.

The 62 and 1/2 grain load shot incredibly well sub moa 2936 fps and SD 5 , But it does no good if you can't work the bolt!

I'd appreciate any help thanks.

Another thing I noticed when firing a string of three, the last shot was always the hardest to lift and extract That's one reason why I'm thinking heat is an issue.