Tartan

WKR

Hi all, first post here and it’s a doozy. I’ve decided to dive in deep and try to build my own pack and frame from the ground up. I just ordered enough raw materials and hardware to do this a couple times over (assuming I’ll have some screw-ups along the way).

Wanted to share my design thoughts and get some feedback. I’ll start with the raw materials I’ve ordered and then share the concept.

Raw materials

- 500D cordura (frame sheet shell, outer surface of harness/belt, lumbar pad shell, pack material)

- Spandura (inside surface of harness/belt, back padding on frame, lumbar pad shell)

- slip-not (lumbar pad shell)

- #69 bonded nylon thread

- ½” XPE closed cell foam

- 1/16" HDPE sheets

- 1”x3/16” 6061 aluminum bar stock

- 1”, 1.5”, and 2” webbing

- ¾” and 1” grosgrain/binding tape

- 1” and 2” sew-on Velcro

- #8 and #10 ykk coil zipper and pulls

- a large assortment of ITW hardware

- ½” grommets

- I haven’t ordered any K-clips yet. But I think those are the last items I would need.

I’m going to start with a 22” pack. And then if it turns out go for a 26”. I’m pretty blatantly copying Kifaru here for the frame, but I’m planning to go with an HPG style shoulder harness. Bag designs are fairly TBD. I’m anticipating the first design to be similar to the Kifaru Apollo, but slightly larger.

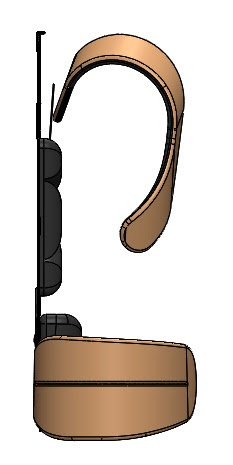

I work in Solidworks all day, so I’ve roughed out a 3D model of the frame so that I could visualize how everything would sew together. It’s missing most of the hardware and webbing, but should convey the general idea.

The biggest question in my head is if I need/want the padding on the frame around the upper back/shoulder blade area. The HPG packs have a slightly taller lumbar pad, but no padding in this area as I believe it floats slightly away from the back. If I decided to remove it, I think I would need to make the lumbar pad a bit taller and maybe a little thinner.

I’ve already mocked this up with cardboard and some random foam I had lying around. It seems to fit pretty well.

What’s everybody think? Am I crazy? Does it look like it will be ok?

Thanks in advance for any input. I will keep this thread updated with progress as it happens. First thing I'll be doing is taking some notes on machine settings for different layers of materials and stitch types.

Wanted to share my design thoughts and get some feedback. I’ll start with the raw materials I’ve ordered and then share the concept.

Raw materials

- 500D cordura (frame sheet shell, outer surface of harness/belt, lumbar pad shell, pack material)

- Spandura (inside surface of harness/belt, back padding on frame, lumbar pad shell)

- slip-not (lumbar pad shell)

- #69 bonded nylon thread

- ½” XPE closed cell foam

- 1/16" HDPE sheets

- 1”x3/16” 6061 aluminum bar stock

- 1”, 1.5”, and 2” webbing

- ¾” and 1” grosgrain/binding tape

- 1” and 2” sew-on Velcro

- #8 and #10 ykk coil zipper and pulls

- a large assortment of ITW hardware

- ½” grommets

- I haven’t ordered any K-clips yet. But I think those are the last items I would need.

I’m going to start with a 22” pack. And then if it turns out go for a 26”. I’m pretty blatantly copying Kifaru here for the frame, but I’m planning to go with an HPG style shoulder harness. Bag designs are fairly TBD. I’m anticipating the first design to be similar to the Kifaru Apollo, but slightly larger.

I work in Solidworks all day, so I’ve roughed out a 3D model of the frame so that I could visualize how everything would sew together. It’s missing most of the hardware and webbing, but should convey the general idea.

The biggest question in my head is if I need/want the padding on the frame around the upper back/shoulder blade area. The HPG packs have a slightly taller lumbar pad, but no padding in this area as I believe it floats slightly away from the back. If I decided to remove it, I think I would need to make the lumbar pad a bit taller and maybe a little thinner.

I’ve already mocked this up with cardboard and some random foam I had lying around. It seems to fit pretty well.

What’s everybody think? Am I crazy? Does it look like it will be ok?

Thanks in advance for any input. I will keep this thread updated with progress as it happens. First thing I'll be doing is taking some notes on machine settings for different layers of materials and stitch types.