From what I’ve read on this forum topic, I believe everybody needs to bubble wrap their scopes on their rifles no matter what brand or model based on this test!!!!! Bubble wrap is cheap, light, and gives you that extra insurance in case of a drop while hunting! Hell, I think you have more of a chance of ruining the crown of the barrel of a rifle with a big fall!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vortex Razor HD LHT 4.5-22x50mm Q&A

- Thread starter Formidilosus

- Start date

Gone4Days

WKR

- Joined

- Oct 29, 2021

- Messages

- 661

Rings are a variable that isn’t being discussed. Which rings were used? I am assuming they weren’t lapped. Being a lightweight scope I know this Vortex won’t be as robust as a 2 lbs scope.

woods89

WKR

I would like to know who is taking this test as gospel. It's been said plenty by those doing this and other tests that a sample size of one is just that. We are adults here, and surely we can read this information, assign a value to it, and be better customers.Nope you misunderstood me

I think every test is useful but it's laughable for everyone to accept one test as gospel.

This will have an extremely negative impact on sales of the LHT, I really hope more testing is done so we can fairly conclude if durability is an issue.

If I had $1100 laying around I would love to buy one post my test results

If it affects sales negatively, so what? If we have to protect gear companies from constructive criticism then we might as well shut this site down.

My Vortex scopes went down the road long before this test came up, due to a combination of my own experiences and others. If they want to win me back then they are going to have to change direction somewhat. This is how the business world works.

If they want a bigger sample size, they could always send Ryan Avery 5 or 10 scopes and we could see if this is just am outlier. It would be pennies compared to all the sponsorship dollars they pay out.

amassi

WKR

- Joined

- May 26, 2018

- Messages

- 3,658

It's in the other threads- do you believe if they were lapped those scope would pass?Rings are a variable that isn’t being discussed. Which rings were used? I am assuming they weren’t lapped. Being a lightweight scope I know this Vortex won’t be as robust as a 2 lbs scope.

Sent from my SM-G991U using Tapatalk

- Joined

- Jan 5, 2012

- Messages

- 8,689

I'm going to lock this thread until I get

home and can move all the scopes to one place and separate the comments from the test, so it's not getting so diluted. Should be back up by Friday.

Sent from my iPhone using Tapatalk

home and can move all the scopes to one place and separate the comments from the test, so it's not getting so diluted. Should be back up by Friday.

Sent from my iPhone using Tapatalk

- Thread Starter

- #286

Formidilosus

Super Moderator

- Joined

- Oct 22, 2014

- Messages

- 8,226

- Thread Starter

- #287

Formidilosus

Super Moderator

- Joined

- Oct 22, 2014

- Messages

- 8,226

Eval and Q&A threads split.

This one is open again.

This one is open again.

- Joined

- Jan 5, 2012

- Messages

- 8,689

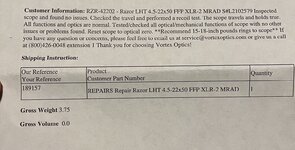

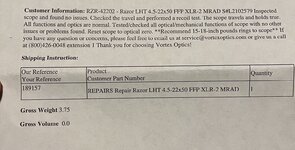

Got the scope back from Vortex. Their communication was outstanding. I do have a VM into them to clarify something. But here is the email. We will listen to their mounting specification and retest.

We’ve received your riflescope, and run it through our full inspections and repair process. All optical and mechanical parameters have been verified, and the optic is now in perfect working condition! The riflescope is ready to head back to you, and if you’ve got any questions on the repair process, what we’ve found in diagnostics, or otherwise – simply shoot me an e-mail, or drop me a line. If I do not hear back from you by Monday, February 7th, I will send it back with my card in the box so you can call at anytime.

When an optic comes into Vortex, we completely eliminate all other variables such as the bases, rings, action screws, ammo, muzzle device etc. We focus on just the optic. The optic is ran through a series of tests and everything was verified. I had a chance to double check it as far as impact testing and tracking. It tracks perfect and doesn't deviate from zero at all. The equipment we have allows us to observe a shift as small as 1/4 MOA or .1 MRAD and I couldn't get it to shift at all, as it stands, outside of any rings or mounts.

I did want to discuss the mounting process you're using. Was this optic put through your Drop test or evaluation? I observed loctite/thread locker on the optic. Our torque specs are 15-18 inch-lbs with no loctite, so dry torque. If you use loctite, it's a lubricant and will lead to higher, unknown torque values. This then leads to a number of issues with an optic including trouble zeroing, holding zero, tracking etc. When you use a quality ring or mount, loctite isn't needed as those screws are under load and as long as they are torqued properly should not loosen.

We also observed some wear on the bottom of the scope, on the bell end or objective end housing. This may have been mounted tight to a barrel or rail etc. I wanted to dig into this further as it can certainly impact the consistency of your setup.

I'm happy to take this a step further for you if it helps restore confidence and mount the optic on a known rifle and set of rings, to our torque specs, and shoot some 3 shot groups in our indoor 100 yard range.

Please let me know if you'd like me to do that or if you'd like to discuss anything further on the phone.

Thank you again for choosing Vortex Optics!

All the Best,

Last edited:

- Joined

- Jan 5, 2012

- Messages

- 8,689

@Ucsdryder if you have additional info from Vortex please post it up here.

ETtikka

WKR

Impressive response, very professional and avoids the root cause of the issue.

They did not and will not perform a drop test, for obvious reasons. Tracking and zero test (without impact) we’re not the problem. They do state they performed an impact test but what does that mean and how do they quantify, 3 shots??

Loctite will lead to higher torque, but that has nothing to do with this failure mode, it should have helped the drop test, not hurt it.

Someone correct me if I am wrong

They did not and will not perform a drop test, for obvious reasons. Tracking and zero test (without impact) we’re not the problem. They do state they performed an impact test but what does that mean and how do they quantify, 3 shots??

Loctite will lead to higher torque, but that has nothing to do with this failure mode, it should have helped the drop test, not hurt it.

Someone correct me if I am wrong

snarkscarbine

FNG

- Joined

- Dec 15, 2021

- Messages

- 82

Remember these scopes are made of a thin aluminum tube. Clamping torque absolutely affects the main-tube-to-erector clearance and can induce all kinds of weirdness related to those tolerances. Por ejemplo all the data Frank at SH collected on the disproportionately high correlation of vertically-split rings and tracking problems. There’s a reason scopes/rings ship with torque specs in the box.Impressive response, very professional and avoids the root cause of the issue.

They did not and will not perform a drop test, for obvious reasons. Tracking and zero test (without impact) we’re not the problem. They do state they performed an impact test but what does that mean and how do they quantify, 3 shots??

Loctite will lead to higher torque, but that has nothing to do with this failure mode, it should have helped the drop test, not hurt it.

Someone correct me if I am wrong

PredatorSlayer

WKR

- Joined

- Jul 20, 2019

- Messages

- 2,242

It depends on how much additional torque was unknowingly applied. Hard to believe a little loctite pushed it over the edge. Almost everybody I know uses loctite for rings. If Vortex is going to claim their scopes can’t be used with loctite, thats almost as damning as not passing the drop test.Remember these scopes are made of a thin aluminum tube. Clamping torque absolutely affects the main-tube-to-erector clearance and can induce all kinds of weirdness related to those tolerances. Por ejemplo all the data Frank at SH collected on the disproportionately high correlation of vertically-split rings and tracking problems. There’s a reason scopes/rings ship with torque specs in the box.

Ucsdryder

WKR

- Joined

- Jan 24, 2015

- Messages

- 5,690

Was the loctite used on the screws holding the rings or was the loctite actually used on the rings to hold the bell in place?

- Thread Starter

- #295

Formidilosus

Super Moderator

- Joined

- Oct 22, 2014

- Messages

- 8,226

Was the loctite used on the screws holding the rings or was the loctite actually used on the rings to hold the bell in place?

Ring cap screws only. However what do you mean by- “or was the loctite actually used on the rings to hold the bell in place?”

ETtikka

WKR

I made my statement about loctite after reading the many post on here about proper scope mounting leading up to these test, and the proving test performed by form on the test weapon.

Form, correct me if I’m wrong but I’m assuming lower torque values without loctite would not make this design pass a drop test.

If the torque was too high, tracking would be affected either by forms test initial testing, not the drop test

Form, correct me if I’m wrong but I’m assuming lower torque values without loctite would not make this design pass a drop test.

If the torque was too high, tracking would be affected either by forms test initial testing, not the drop test

- Thread Starter

- #297

Formidilosus

Super Moderator

- Joined

- Oct 22, 2014

- Messages

- 8,226

For those questioning the loctite causing too much torque- go find what the specs for the difference between dry torque on ring screws, and wet torque with loctite (not generic “wet”) on ring screws. It’s not some unknowable number. Then go back and look at what the rings that were used specified, and what I wrote that the rings were torqued to.

ETtikka

WKR

If I was vortex I would blame loctiteRemember these scopes are made of a thin aluminum tube. Clamping torque absolutely affects the main-tube-to-erector clearance and can induce all kinds of weirdness related to those tolerances. Por ejemplo all the data Frank at SH collected on the disproportionately high correlation of vertically-split rings and tracking problems. There’s a reason scopes/rings ship with torque specs in the

- Thread Starter

- #299

Formidilosus

Super Moderator

- Joined

- Oct 22, 2014

- Messages

- 8,226

Form, correct me if I’m wrong but I’m assuming lower torque values without loctite would not make this design pass a drop test.

If the torque was too high, tracking would be affected either by forms test initial testing, not the drop test

Correct on all. The scope was mounted and remounted no less than four times. Torque values from 16 in-lbs dry to 25 in-lbs wet.

snarkscarbine

FNG

- Joined

- Dec 15, 2021

- Messages

- 82

I’m not an engineer and I don’t actually know what I’m talking about, but I’ve seen evidence than excessive clamping force on a scope can make it do weird things. 16in-lbs dry to 25in-lbs wet (at a pretty conservative 20% torque reduction) is a 95% increase in clamping force. I don’t know if that would cause the issue you saw or not, but it’s not insignificant given the fact that incorrect clamping force can affect function.Correct on all. The scope was mounted and remounted no less than four times. Torque values from 16 in-lbs dry to 25 in-lbs wet.

Similar threads

- Replies

- 21

- Views

- 2K

- Replies

- 1

- Views

- 313

- Replies

- 3

- Views

- 274

- Replies

- 3

- Views

- 323

Featured Video

Stats

Latest Articles

-

Idaho Mule Deer Management with Eric Freeman

-

TT#28 Idaho Bear Hunting with Roger Holscher and Chris Young

-

Rockstar Research with Kevin Monteith

-

Hunting Big Mule Deer: Obey the Wind & Still-Hunting

-

TT#27 DIY New Zealand Hunting with Australian Duo Miller and Pitts

-

Fewer Bucks, More Fawns?

-

Mathews Lift Review

-

Wyoming Range Winter Wrap-Up with Jeff Short

-

The Pursuit with Cliff Gray

-

Mile High Mule Deer Seminar