Kevin Dill

WKR

- Joined

- Aug 26, 2014

- Messages

- 3,158

DIY Electric Bear Fence - Complete Pics p 2

After many trips to the backcountry and some bad run-ins with bruins, I've come down on the side of taking an electric fence along whenever possible. My partner bought the UDAP kit but I am truthfully not at all impressed with much of the components in it. The posts especially are just shy of being useless in my mind. I have used electric fences many times around my farm and understand the mechanics very well, so I decided to build my own GOOD fence while keeping it packable and light.

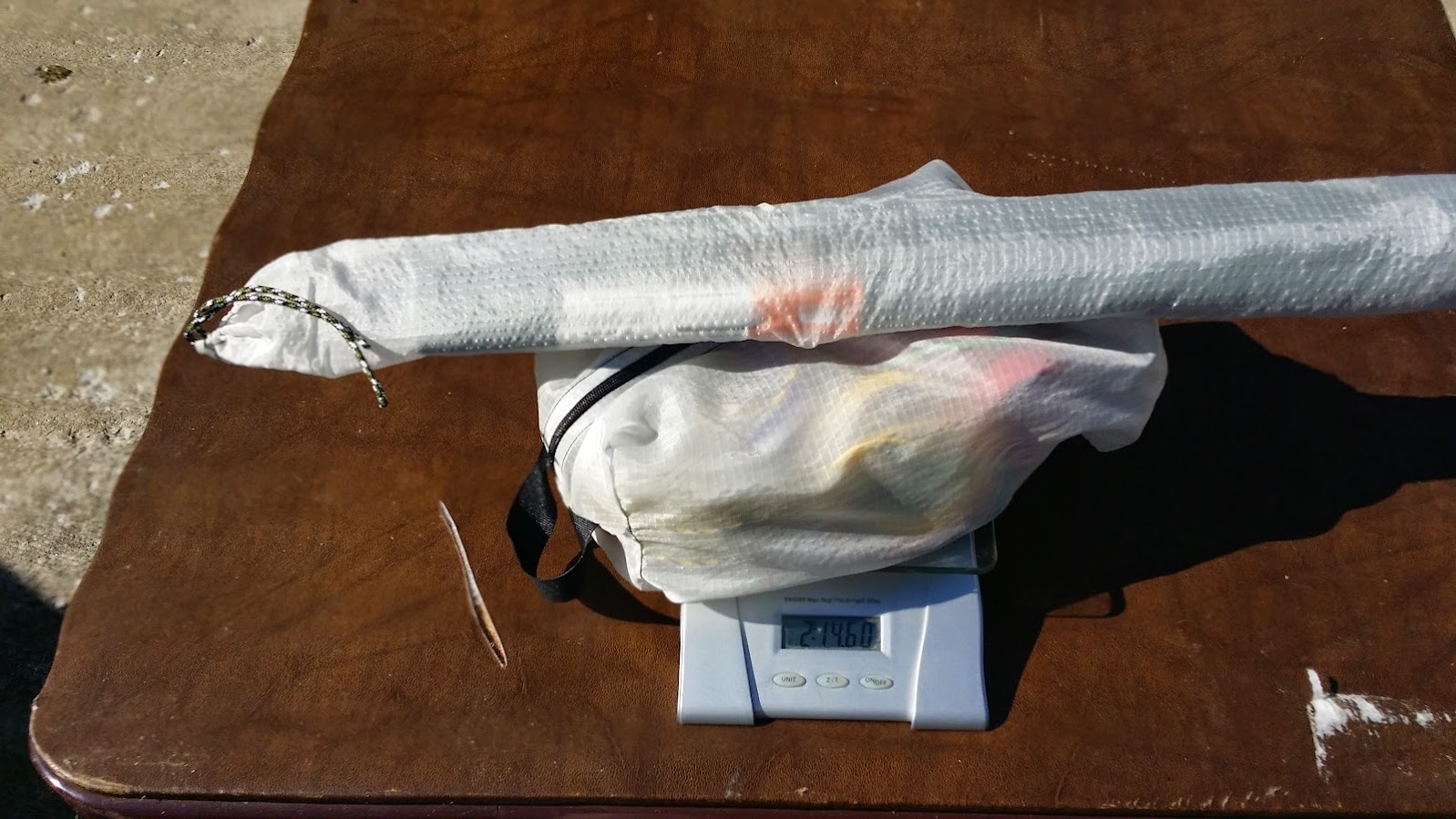

I started by ordering a Speedrite AN20 energizer, 1" white equine tape (instead of wire), insulators, tape-connectors and a couple odd components. That was the easy part. Making good posts required some thought. After much debate I ended up buying a dozen cheap carbon arrow shafts and extra threaded glue-in inserts. My plan is to cut each 30" shaft into 2 x 15" pieces, and glue inserts in each end of each piece. I'll use 8-32 all-thread to make the connections. Three sections screwed together will make a 45" post to insert in the ground. I'll use a light field point for the bottom tip of the post. I'll make 6 total posts and my enclosure will be hex-shaped. I also will make paracord loops and epoxy them into the top of each post which will make for easier guy-out bracing if needed. When it's all done everything will fit in a 16" x 8" bag.

I didn't really do this to save money, though I will do exactly that. I want a sturdy fence with no hassles and it must work well. I also wanted it to be compact and as light as possible. One thing I'm still exploring is some way to make and attach a very low profile insulator suitable for the 1" tape. I've been thinking about pieces of 2"-long rubber tubing slid down over the shaft (post) to the correct height. The 1" white tape would be placed against the rubber tube and secured with a small zip-tie or some other form of easy attachment.

Your thoughts?

After many trips to the backcountry and some bad run-ins with bruins, I've come down on the side of taking an electric fence along whenever possible. My partner bought the UDAP kit but I am truthfully not at all impressed with much of the components in it. The posts especially are just shy of being useless in my mind. I have used electric fences many times around my farm and understand the mechanics very well, so I decided to build my own GOOD fence while keeping it packable and light.

I started by ordering a Speedrite AN20 energizer, 1" white equine tape (instead of wire), insulators, tape-connectors and a couple odd components. That was the easy part. Making good posts required some thought. After much debate I ended up buying a dozen cheap carbon arrow shafts and extra threaded glue-in inserts. My plan is to cut each 30" shaft into 2 x 15" pieces, and glue inserts in each end of each piece. I'll use 8-32 all-thread to make the connections. Three sections screwed together will make a 45" post to insert in the ground. I'll use a light field point for the bottom tip of the post. I'll make 6 total posts and my enclosure will be hex-shaped. I also will make paracord loops and epoxy them into the top of each post which will make for easier guy-out bracing if needed. When it's all done everything will fit in a 16" x 8" bag.

I didn't really do this to save money, though I will do exactly that. I want a sturdy fence with no hassles and it must work well. I also wanted it to be compact and as light as possible. One thing I'm still exploring is some way to make and attach a very low profile insulator suitable for the 1" tape. I've been thinking about pieces of 2"-long rubber tubing slid down over the shaft (post) to the correct height. The 1" white tape would be placed against the rubber tube and secured with a small zip-tie or some other form of easy attachment.

Your thoughts?

Last edited: