ID_Matt

WKR

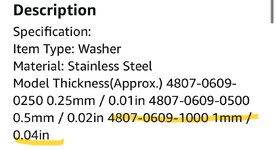

It may have been discussed on here before but maybe I missed it. Trying to get my tikka action torqued in to a stockys VG at a reasonable torque and the action screws want to push through the bottom plastic, even much past 40 in lbs. Trying to avoid spending the money on an aftermarket bottom metal. Is there a good solution? Washer or different screw?