You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Short Action Customs modular sizing die

- Thread starter Lawnboi

- Start date

ResearchinStuff

WKR

tagging in, I've been eyeing the SAC dies myself.

- Thread Starter

- #3

I’ll start by mentioning that I first tried the SAC bushings for my wilson dies. SAC uses some different geometry in their bushings, which really made sense in my mind, and in practice made sense on the press. Just a sac bushing in my wilson die was enough to eliminate the doughnut on my brass. Unfortunately their bushings have been going quick and I was unable to get the size I really wanted, that and wanting a 6creed barrel for my next on my match gun made grabbing the modular sizing did easy.

Finally pulled it out and played with it. Nice packaging. Shipped quick. Had instructions.

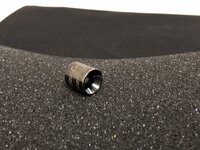

Below is a picture of the bushing used in this die, different in that it sizes the neck along with bumps the shoulder. Really slick in that no doughnut is formed on the brass. It also allows some super fine tuning with shims, and the ability to use different calibers in the same die, ie 6creed, 25creed, 22creed. The bushing is polished and coated, as are their standard die bushings. Surface is very slick, and they don’t Gall annealed case necks like Redding or wilson have for me. I had a good idea what I needed being that my brass for this rifle is on its 8th loading. Edit I’ll mention that all sac bushings Iv used have been exactly .001 under what I used for Redding bushings. I think it’s due to the geometry, but something to keep in mind. I check all my neck tolerances with pin bushings to keep things the same, so a thou is immediately noticeable.

Screwed it into my mec marksman to touch and gave it a slight cam over. Started with my +.010 Redding shell holder, one slight adjustment on the cam over and I was there. Repeated on the rest of my 12 test pieces. The honing done on this die and bushing made sizing significantly easier than with my wilson FL sizer it replaced.

So that’s about it. I have a carbide mandrel coming in the mail from sac and am going to give that a go when it arrives. If I can eliminate a pull of the handle into my sinclair expander mandrel I’ll take that as a win.

Time to start cranking out some brass. July is a busy match month for me, it will have 500 pieces through it by the time July is over.

So far it’s everything I was hoping it would be.

Finally pulled it out and played with it. Nice packaging. Shipped quick. Had instructions.

Below is a picture of the bushing used in this die, different in that it sizes the neck along with bumps the shoulder. Really slick in that no doughnut is formed on the brass. It also allows some super fine tuning with shims, and the ability to use different calibers in the same die, ie 6creed, 25creed, 22creed. The bushing is polished and coated, as are their standard die bushings. Surface is very slick, and they don’t Gall annealed case necks like Redding or wilson have for me. I had a good idea what I needed being that my brass for this rifle is on its 8th loading. Edit I’ll mention that all sac bushings Iv used have been exactly .001 under what I used for Redding bushings. I think it’s due to the geometry, but something to keep in mind. I check all my neck tolerances with pin bushings to keep things the same, so a thou is immediately noticeable.

Screwed it into my mec marksman to touch and gave it a slight cam over. Started with my +.010 Redding shell holder, one slight adjustment on the cam over and I was there. Repeated on the rest of my 12 test pieces. The honing done on this die and bushing made sizing significantly easier than with my wilson FL sizer it replaced.

So that’s about it. I have a carbide mandrel coming in the mail from sac and am going to give that a go when it arrives. If I can eliminate a pull of the handle into my sinclair expander mandrel I’ll take that as a win.

Time to start cranking out some brass. July is a busy match month for me, it will have 500 pieces through it by the time July is over.

So far it’s everything I was hoping it would be.

Last edited:

Kimber7man

WKR

Nice write up! Are you using imperial sizing wax? Wondering how the die handles wax with the geometry of the neck/shoulder bushing.

- Thread Starter

- #5

Yes imperial wax. I havnt had a problem yet, I just sized 180 pieces on it without touching anything. Brass exterior geometry was unchanged from start to finish according to my rudementary tools (calipers and Hornady guages)Nice write up! Are you using imperial sizing wax? Wondering how the die handles wax with the geometry of the neck/shoulder bushing.

Seems to spit a little more wax out the bottom but that’s all so far.

The geometry of the neck portion of their bushings both the shouldered and non is a game changer for loading IMO. Even the non shouldered version for use is normal dies makes sizing with a bushing smoother, and causes very minimal doughnut.

Im impressed enough that I want another one. Hopefully they continue to make more calibers because this die is a game changer.

ResearchinStuff

WKR

Have you switched bushings for something in another family? Specifically, creedmoor to br? If so, was the shoulder bump correct or did you have to adjust it?

- Thread Starter

- #7

The die is for family only, so the creedmoor die will only size creedmoor brass be it 22,6,25,6.5. I have only sized 6.5, but have a 6 creed barrel on order for next season.Have you switched bushings for something in another family? Specifically, creedmoor to br? If so, was the shoulder bump correct or did you have to adjust it?

ResearchinStuff

WKR

I guess I mixed up the descriptions of their modular sizing die and their seating die. Thanks for saving me some $

- Thread Starter

- #9

Today I tried out the carbide mandrel. The more I reload, the more I want to make use of my time more efficiently. The mandrel will hopefully eliminate a pull of the handle. Being that you can buy them in .0005 increments means that the bushing, along with mandrel size makes it easy to control consistent neck tension. I have never been an expander ball person, and always run a mandrel through as a second step. The mandrel on the SAC die can be set and adjusted to contact the neck directly after the bushing releases it. It’s said to reduce runout being that the neck is still being held by the bushing while being pulled out onto the expander. If it does… who knows, honestly I don’t have the equipment to test that theory.

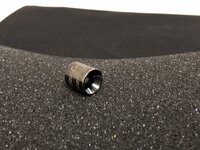

What I do know is as far as I know this is the only expander mandrel thats adjustable. Iv tried some other dies with similar style expanding mandrels or buttons in them and they always worked the living shit out of the brass. By allowing the user to choose the size, makes for minimal working of the brass and smooth press operation. The Lapua in the picture below is on its 10th loading and showing no signs of giving up.

Apparently SAC has available a version of this mandrel with a decapping pin that isn’t on their site yet. This would make the ultimate one pull setup and is the direction I’ll be headed. If I can make 3 pulls of the press into one it’s going to save ALOT of time at the bench.

What I do know is as far as I know this is the only expander mandrel thats adjustable. Iv tried some other dies with similar style expanding mandrels or buttons in them and they always worked the living shit out of the brass. By allowing the user to choose the size, makes for minimal working of the brass and smooth press operation. The Lapua in the picture below is on its 10th loading and showing no signs of giving up.

Apparently SAC has available a version of this mandrel with a decapping pin that isn’t on their site yet. This would make the ultimate one pull setup and is the direction I’ll be headed. If I can make 3 pulls of the press into one it’s going to save ALOT of time at the bench.

Last edited:

- Thread Starter

- #10

rayporter

WKR

looks like a copy of neil jones dies and bushings. they have worked for me since 1985.

especially good for forming.

especially good for forming.

- Thread Starter

- #12

Got to use short action customs customer service.

10pm I went to size some 6 creed brass found out I got a small/medium mandrel instead of medium. Email was sent.

By 8am the next day I received an email with shipping information for a correct mandrel along with prepaid postage to send the wrong one back.

Iv got a lot of rounds now on these dies, and I see they keep coming out with more.

I’ll never buy another bushing die that isn’t like this one ever again.

10pm I went to size some 6 creed brass found out I got a small/medium mandrel instead of medium. Email was sent.

By 8am the next day I received an email with shipping information for a correct mandrel along with prepaid postage to send the wrong one back.

Iv got a lot of rounds now on these dies, and I see they keep coming out with more.

I’ll never buy another bushing die that isn’t like this one ever again.

- Thread Starter

- #13

NevadaMike

WKR

- Joined

- Aug 4, 2020

- Messages

- 543

It sounds like you have a much better grasp on the precision side than I do. I am not a bench rest shooter just a hunter that probably puts too much time into hunting ammo. Whidden talks about non-bushing dies eliminating the doughnut problem you mentioned earlier as well as having less runout. After listening to this I finalized my load and ordered custom honed Forster dies and seating stems for the brass and projectile I am using. Am I leaving too much on the table by going this route?

Last edited:

- Thread Starter

- #15

It sounds like you have a much better grasp on the precision side than I do. I am not a benchers shooter just a hunter that probably puts too much time into hunting ammo. Whidden talks about non-bushing dies eliminating the doughnut problem you mentioned earlier as well as having less runout. After listening to this I finalized my load and ordered custom honed Forster dies and seating stems for the brass and projectile I am using. Am I leaving too much on the table by going this route?

I think you just lose the ability to adjust. Beyond the modularity aspect, the sac die allows you to adjust both the mandrel and the bushing, to work the brass as little possible. Specifically if you’re not annealing, and even if you are, eventually Iv had to go down in bushing size. That and I’m not sure on the expander ball vs the mandrel, would be an interesting comparison. I hate reloading, currently if it won’t do decap/size/expand in one step I’m not going to build it for any volume shooting.

I think the Forster die honed is the only other option as I’m not a fan of bushing dies that only size the neck. In the Forster it is nice you can adjust the expander ball, but you’re still stuck with that ball only.

They are not cheap and I get that. I have had better results with them as far as accuracy goes, and I’m not a bench rest shooter either. I have Had a bunch of standard dies as well, while they worked I just didn’t get the consistent results.

I also am not the shooter I was years ago, so maybe that has to do with it. I do know my reloading process is way faster and way more consistent then with what I started with.

Hopefully that makes sense. Lots of unorganized thoughts

Kimber7man

WKR

@Lawnboi are you switching back and forth from 6 to 6.5, and if so what do you change going between them?

- Thread Starter

- #17

Not 6.5, but I will be for 22 creed.@Lawnboi are you switching back and forth from 6 to 6.5, and if so what do you change going between them?

My plan, so long as headspace is close, is to use my Redding comp shell holder kit to adjust headspace. That’s normally how I end up doing it anyways. So instead of the die I’m adjusting headspace between the difference in cartridge by adjusting my shell holder.

Swapping a bushing and a mandrel is pretty much set and forget, you can adjust them with shims but I havnt seen the need to adjust that small. I just use my Redding shell holders to adjust, and set my press to contact the die with a little cam over.

Kimber7man

WKR

10-4, I have the SAUM die and wanting to switch between 6.5 and 7 eventually.

BBob

WKR

different in that it sizes the neck along with bumps the shoulder.

FWIW Neil Jones has been making his bushings like the SAC for probably 40+ years. I have several of his dies. His are also somewhat modular in that you can order additional bodies for a tighter or looser body to vary the amount of sizing. He initially wants 3 times fired brass to fit the body to your brass. Looks like SAC has expanded on his dies with more features possible.I think the Forster die honed is the only other option

Warner Tool as well.FWIW Neil Jones has been making his bushings like the SAC for probably 40+ years. I have several of his dies. His are also somewhat modular in that you can order additional bodies for a tighter or looser body to vary the amount of sizing. He initially wants 3 times fired brass to fit the body to your brass. Looks like SAC has expanded on his dies with more features possible.

WTC NECK AND SHOULDER BUSHING | Warner Tool Company

The Neck and Shoulder Bushing is compatible with the WTC Sizing Dies and sizes the neck and shoulder of the shooter's rifle brass.

www.warner-tool.com

www.warner-tool.com

Similar threads

Latest posts

-

Can't Reach Out For Help From Guys Who Have Been There????

- Latest: Glockster26

-

-

-

Featured Video

Stats

Latest Articles

-

Gunnison Mule Deer and Beyond with Brandon Diamond

-

Idaho Mule Deer Management with Eric Freeman

-

TT#28 Idaho Bear Hunting with Roger Holscher and Chris Young

-

Rockstar Research with Kevin Monteith

-

Hunting Big Mule Deer: Obey the Wind & Still-Hunting

-

TT#27 DIY New Zealand Hunting with Australian Duo Miller and Pitts

-

Fewer Bucks, More Fawns?

-

Mathews Lift Review

-

Wyoming Range Winter Wrap-Up with Jeff Short

-

The Pursuit with Cliff Gray