wind gypsy

WKR

- Joined

- Dec 30, 2014

- Messages

- 8,382

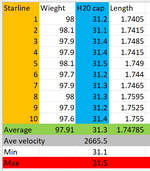

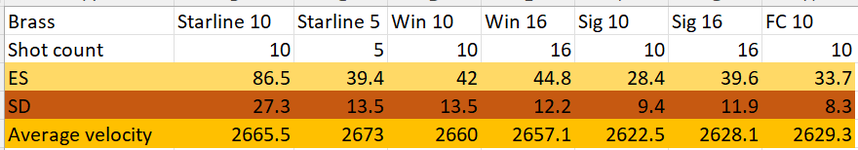

Better ES/SD. I would think with careful measurement you’d see the consistency, but I’ve never bothered. I let my testing/results inform my opinion. I chase a very high standard for my ES. Sub 20 for sure, and I like to be closer to 10 across a 10 shot string. I’ve gotten to where I won’t even consider a cartridge if there isn’t Lapua brass. It’s just the easy button, if your process is consistent, with good bullets, I’ve never had an issue. With other brass brands, it’s been all over the map.

I realize that level of consistency doesn’t really “matter” for most hunting that most people do. But if you’re into any sort of longish range shooting, it’s a very important variable to take out of the equation

ES of 10 over 10 shots, consistently, is pretty damn tough in my experience. I'd go crazy trying to hit that I think.